What are hydronic heating systems and how do they work in your RV?

Hydronic heating systems are rapidly becoming the heating system of choice on diesel pushers versus forced air furnaces. Hydronic heat offers even heat distribution and moist, comfortable heating. It utilizes a boiler that pumps antifreeze through a series of heat exchangers located throughout the coach. It also provides domestic hot water heating, eliminating the need for a traditional hot water heater. The two brands that are common in the RV industry are Aqua-Hot and Oasis.

RV Heat Sources

A hydronic heating system can be powered by a diesel burner as well as an electric heating element. In some cases a propane fired boiler is used in smaller RVs but for this article we’ll just stick to the diesel fired units common to most diesel pushers. Diesel fuel has more BTU per gallon than propane. Plus, the fuel tank is of greater capacity because it utilizes the coach’s diesel tank rather than a smaller LP tank mounted in the coach. Not only is this more cost efficient but it also greatly extends the run time between refueling.

Propane has a BTU rating of 91,500 BTU per gallon while #2 diesel fuel is rated at 139,200 BTU per gallon. Operating a 50,000 BTU burner on propane for 8 hours will require 4.37 gallons of propane while running that same burner on diesel fuel will only require 2.87 of fuel due to the higher BTU content of diesel fuel. If your LP fired burner is fed from a 32 gallon propane tank you can run that burner for a maximum of 58.56 hours while running a diesel burner from a 100 gallon fuel tank will allow you 278.4 hours of run time until you’ll need to refuel.

In addition to the diesel burner, hydronic heating systems also have an electrical heating element that can be used. A typical 1,650 watt heating element can deliver 5,630 BTU. This isn’t as great as a 50 KBTU diesel burner but it is capable of heating the coach when it’s cool (but not cold) out. It’s also possible to operate both the burner and the electric element at the same time for additional heating capacity.

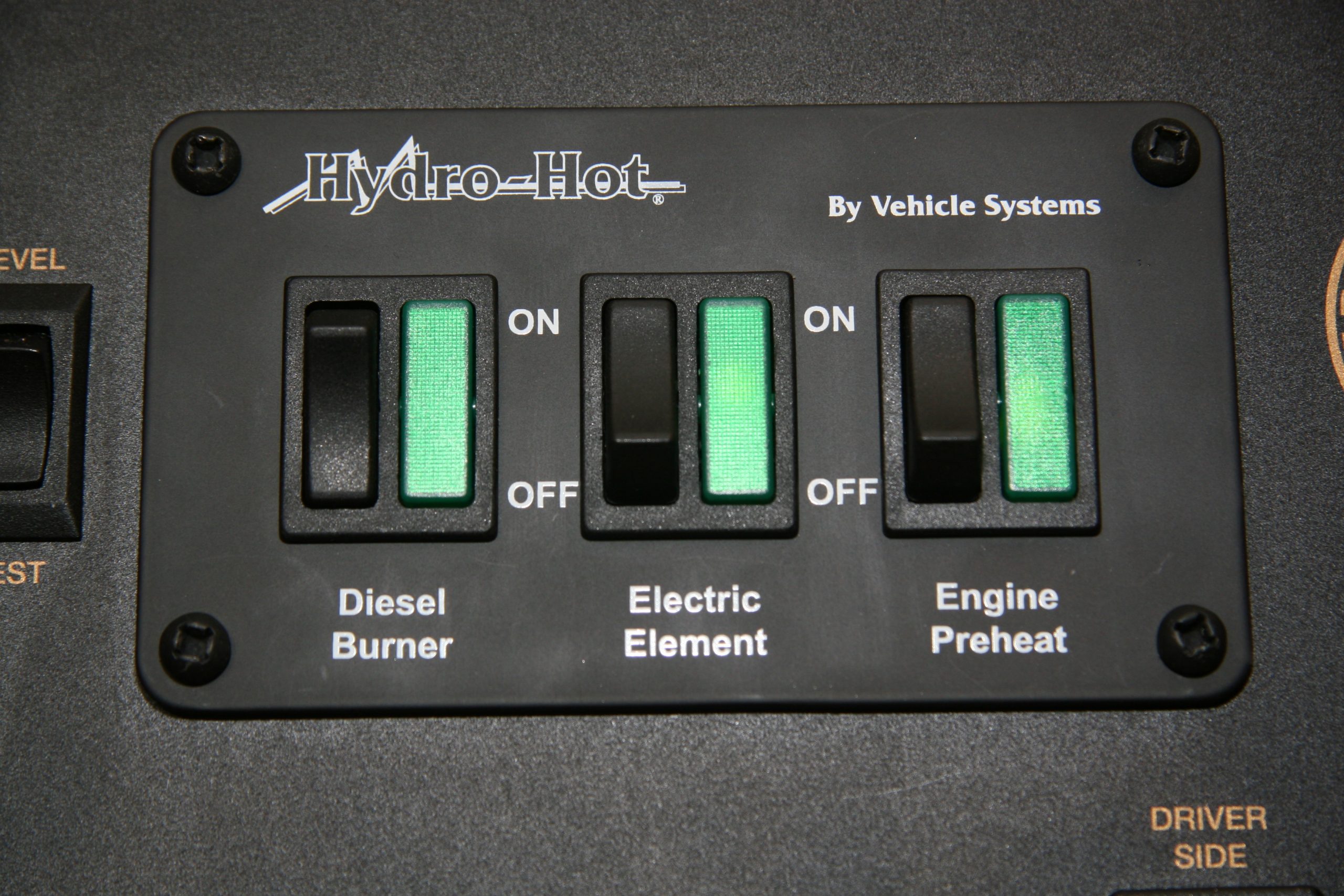

Most units are also equipped with a Motoraide or engine assist connection. This allows the hot engine coolant to be used to add additional free heat to the boiler when driving. This engine to boiler loop can also be used as an engine preheat that uses the boiler’s heat to preheat the engine for cold start assistance if so equipped.

Aqua-Hot vs. Oasis

Both the Aqua-Hot and Oasis systems are similar in operation. They both utilize a boiler to heat up antifreeze so that it can circulate through a closed heating loop. There are heat exchangers placed in various locations in the loop to provide heat to the coach interior as well as any basement area that needs to be protected from freezing. They also provide domestic hot water but there are a number of differences in how the units are constructed to meet these needs.

The popular Aqua-Hot 450 supports a claimed 50,000 BTU burner, although the latest advertised specs state 65,000 BTU, and a 6 gallon boiler tank. It also sports a 1,650 watt electric heating element on a 20 amp breaker. Hot water temperature is always rated at a delta, which is the difference between the temperature of the incoming cold water to the outgoing heated water. The 450D is rated at a 60 degree delta at 1.5 GPM water flow. If the incoming water is frigidly cold then you’ll only be able to raise it by 60 degrees. If you exceed the 1.5 GPM flow rate you will also lose the ability to keep the antifreeze in the boiler tank from holding its heat so you’ll need to watch your water flow on those long hot showers or they will finish up as cold showers.

For more more on RV water systems, read Mark’s blog, An RVers Guide To Water

An Aqua-Hot 450D system.

The Aqua-Hot system also will shut off the interior heat exchangers when hot water is being used so that all available BTU can be dedicated to heating water. The interior heating will resume once the water flow stops. The Aqua-Hot claimed BTU ratings are suspect however . The burner uses a .35 GPM burner nozzle. Doing the math you can see that this is only 39,200 BTU per hour – not 50,000 BTU.

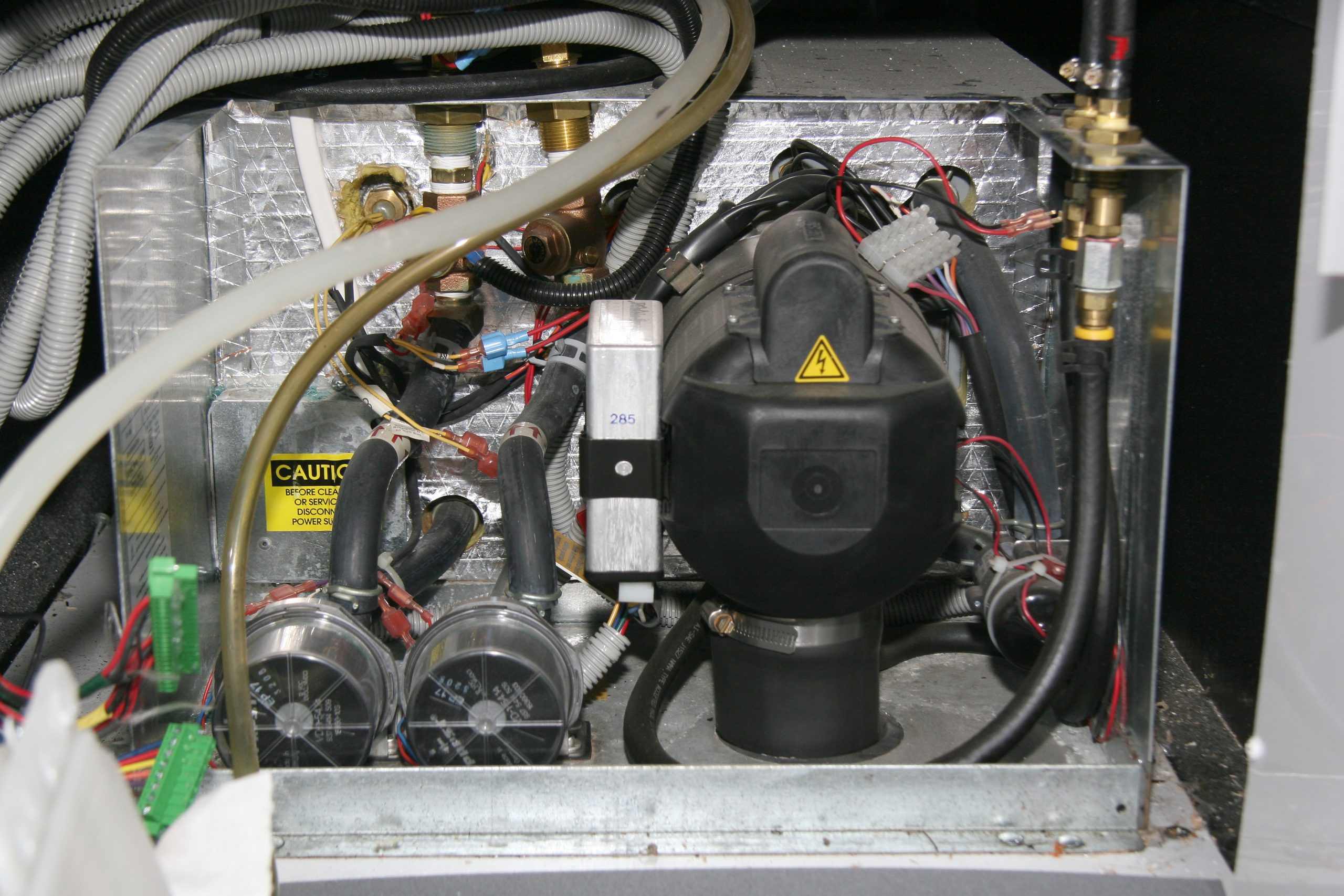

An Aqua-Hot 450D as installed in my Entegra Cornerstone.

An opened-up view of the Aqua-Hot system.

Oasis also makes a 50,000 BTU system called the Oasis NE, which uses a 7.5 gallon boiler tank. It utilizes a pair of 1,500 watt electric heating elements, producing up to 10,236 BTU on two 15 amp breakers. You can operate one or both at the same time. This will let you utilize the electric heat to a bit lower temperatures before needing to switch on the diesel burner. Hot water heating is also rated at a 65 degree delta at 1.5 GPM although the Oasis NE does not interrupt interior floor heat while hot water is being consumed. The burners use a .44 GPM fuel nozzle, which equates to a realistic 49,280 BTU.

Oasis also makes a larger Oasis NE-S version. This slightly larger version is the ultimate in hydronic heating, with a claimed 85,000 BTU burner rating and a 13.75 gallon boiler tank. It has the same dual 1,500 watt heating elements as the Oasis NE but the 60 degree delta for hot water is now increased to 3 GPM with no floor heat interruption. The burner uses a 0.79 GPM burner nozzle.

The above calculations are based upon an 80% factor in the BTU of diesel fuel. While diesel fuel does have 140,000 BTU per gallon about 20% of that is lost as heat in the exhaust, leaving 80% to do the actual work of heating. So I used 112,000 BTU when doing the above calculations.

An installed Oasis NE system in a Showhauler motorhome.

Operation

Your system will have a few switches to operate the boiler. These switches may be rocker switches, or in a dedicated control panel or embedded in a multiplex control panel such as a VegaTouch screen. These switches are used to turn on the diesel burner and electric heating elements. There may also be a switch for an optional engine preheat feature if so equipped. These controls supply power to operate the boiler. If they are not on you won’t get any heat. Once the boiler heats up to its designated cutout temperature it will stop. Once the boiler’s temperature drops below the cut-in temperature it will start up again to raise the heat level of the boiler antifreeze.

The diesel burner and electrical heating element are controlled by a switch panel.

The antifreeze in the boiler is used to circulate through a couple of closed loops via circulating pumps. Interior heat exchangers are inserted into these loops at key locations to evenly distribute heat throughout the coach interior. These circulating pumps are controlled by the coach’s HVAC thermostat controls. Whenever the thermostat calls for heat, the circulating pumps will circulate hot antifreeze through the heating loop and heat exchangers. The fans on the heat exchangers will switch on to deliver the heat to the interior but only if the boiler is hot. This is to prevent blowing cold air from the heat exchangers if the antifreeze hasn’t warmed up yet. Once it is warmed up, the fans will engage and heat the coach interior. If the boiler cools down the fans will stop, allowing the boiler to regain its temperature before switching on again. When first starting up a hydronic system, you will have to wait a few minutes until the boiler warms up.

These systems have two heating loops, each powered by a circulating pump. A number of heat exchangers can be connected to these loops and these heat exchangers are connected to up to 5 heating zones. One heating zone may be used for the main cabin interior heating while a second heating zone may be used for the bedroom and rear bath heating area. A third zone may be used for basement heat while a fourth zone may be used for hydronic floor heat, in the case of an Entegra Coach. The layout of these zones and to which circulating loop they are assigned is up to the coach manufacturer’s discretion. Each zone will have individual thermostat control with remote sensors. This can be multiple thermostats, a multi-zone thermostat or part of a VegaTouch multiplex system. In many cases, there will be a separate manually-operated thermostat in the basement to control the basement zone that protects the fresh water system from freezing. If you just want to keep minimal heat in the coach, you will still need to leave either the electric heating element or diesel burner switched on or else you won’t get any heat.

Many coaches utilize a separate thermostat to control the basement heat.

The Motoraide loop to the engine will provide a bit of heat when driving. Typical BTU output for this is in the neighborhood of 10,000 BTU but will vary from coach to coach. It will keep the boiler hot so that you will have hot water when you stop and can give you a bit of interior heat but if it’s relatively cool out you will want to use the diesel burner as well. Still, the extra 10 KBTU is a help and will give you some free heat and save some diesel fuel. This system utilizes the engine’s water pump to circulate engine coolant through an internal heat exchanger inside the boiler via regular automotive heater hoses. You do not have to switch on any engine preheat pump for this to happen.

The optional engine preheat feature utilizes the same heater hoses but adds a circulating pump that pumps the engine antifreeze in the opposite direction. This is used to provide heat from an operating hydronic heating system boiler to a cold engine to make it easier to start. Note that this is not part of the engine block heater, which is a second preheat device supplied by the chassis manufacturer. The hydronic preheat system will actually heat up your engine faster than the block heater because it has more BTU. You can also use it when you are parked in a place where you do not have access to electricity because you can run your boiler on diesel fuel in the middle of Alaska if you need to preheat your engine. This is an optional feature so it depends on if the coach manufacturer uses it. If you stay out of cold areas it may not be of much use for you.

Hydronic systems also provide domestic hot water in addition to heat. The hot boiler antifreeze transfers heat to a coil that heats the fresh water as it passes through the coil on its way to your hot water faucets. A traditional water heater that uses a tank to store hot water will quickly run out of hot water once the tank is depleted so no long hot showers are possible. The hydronic system is a true on-demand system that will heat the water as it passes through the heating coil. The only caveat is that you have to limit the flow so that the boiler can keep up. The typical system has the ability to raise the water’s temperature 60 degrees over the temperature of the incoming water. If your water is very cold you’ll be limited in how hot you can get the water but if the incoming water is warmer you’ll be able to heat it to a higher temperature. Typically, this is rated at a 1.5 GPM flow rate. If you exceed that rate, the boiler won’t be able to keep up and as the boiler temperature begins to drop – so will the temperature of your hot water output. Using higher flow rates can work for a short time but if you really need a long hot shower, you’ll want to keep the flow rate beneath 1.5 GPM.

Maintenance

Anything mechanical will require a bit of maintenance every now and then. A hydronic heating system isn’t a high-maintenance item but when you consider that these systems have a diesel-powered flame that heats a boiler and circulating pumps that cycle antifreeze through heat exchangers, there are a few points to watch for.

A typical system requires an annual service, which pretty much centers on the diesel burner. The diesel burner pumps fuel through a small nozzle into the burner chamber and is ignited by a spark. The nozzle itself has a minute orifice that is designed for a specific flow rate and a precise conical pattern. During normal use, the diesel fuel that passes through the nozzle will wear out the orifice, resulting in excess diesel fuel flow. This excess fuel will cause fouling of the swirler flues that are designed to create the correct circular airflow inside the burner’s combustion chamber. The end result is that your hydronic heating system runs rich, causing stinky exhaust and puffs of smoke. This wear occurs from use, not time, so if you run your diesel burner quite often you might require service sooner than the arbitrary one year interval.

The burner nozzle, electrodes and flame sensor are part of the annual service.

The combustion chamber needs to be cleaned and vacuumed as part of the service..

Nozzles cannot be cleaned but they are inexpensive and should be replaced. The annual service also entails replacing the fuel filter and a thorough inspection of the burner. It’s important to keep the burner head clean, especially the electrodes and flame sensor photocell. At the same time a good vacuuming of the combustion chamber and cleaning of the swirler to ensure the ports are clean is necessary. Finally, a quick check of the fuel pump pressure will ensure that everything is up to snuff.

The fuel filter for the diesel burner needs to be changed annually.

Assuming that your system is functioning without any major issues, the only thing left is the antifreeze. Hydronic heating systems do not use automotive antifreeze, which includes water pump lubricants, anti-corrosion inhibitors and other additives designed for engines as well as freeze protection. A hydronic heating system uses an antifreeze that protects against freeze damage but it is designed for the best heat transfer. While most automotive antifreeze is Ethylene Glycol (EG), hydronic systems require Propylene Glycol (PG). The correct antifreeze will be available from Camco or Century and they are labeled as GRAS, which means Generally Recognized As Safe because they are not toxic, unlike EG. Your hydronic heating system will be equipped with a poly overflow tank so that you can see the level in your boiler. If it becomes discolored and smells burnt, it may be time to have your RV tech flush the system and replace the antifreeze.

While the boiler and heating loops are a sealed system, it always seems that they need a little topping off every now and then, so most owners carry a spare jug along. Pure antifreeze needs to be mixed with water about 50/50. Antifreeze is available in jugs filled with concentrated antifreeze that needs to be mixed with water or as a preformulated 50/50 mix. If you do buy the concentrated antifreeze, be sure to use distilled or deionized water when diluting it to a 50/50 mix to prevent minerals from tap water from accumulating in your hydronic system. You can dilute it a bit beyond the 50/50 mix which covers to -42F. In fact, the best heat transfer is at 60% water and 40% antifreeze. That will drop the freeze temperature a bit, but not significantly. A quick check of your antifreeze’s freeze point with a refractometer will verify your current freeze point. If the freeze point is too high, you can add a bit of concentrated antifreeze to bring the freeze protection level back to where it needs to be.

Really, with a little bit of care and understanding you’ll be able to enjoy your hydronic heat for a long time.

Mark Quasius is the founder of RVtechMag.com, the past Midwest editor of RV Magazine, writes for numerous RV-related publications and a regular Contributor to FMCA’s Family RVing Magazine. Mark and his wife Leann travel in their 2016 Entegra Cornerstone.